Structural Steel

Introduction

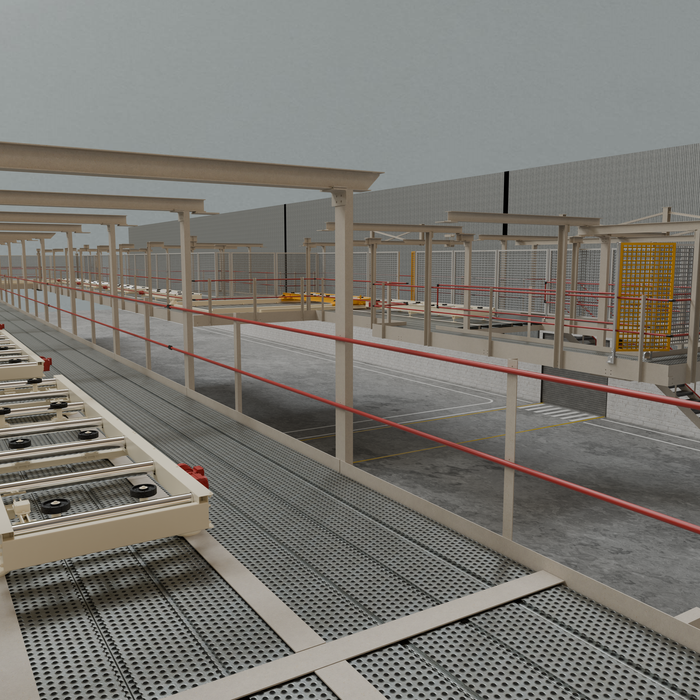

Floor-Mounted Steelwork

Suspended Steelwork

Structural Loadings

Utilising our systems and expertise for structural steelwork enhances accuracy, efficiency, and collaboration. It enables precise visualisation and simulation in a digital, risk-free environment, reducing errors and costly rework. By detecting clashes and issues early, it ensures a seamless fit during installation and ensures timely delivery. Improved communication streamlines approvals, while better planning and material optimisation cut costs and speed up manufacture.

Integration into the surroundings is always critical to fit within confines of other equipment installed around, above or underneath the new structure. Likewise when attaching to or extending existing structures, so our team operate dynamically within the supply chain to achieve this – liaising as required with other providers and teams working within the local area, sharing data to ensure right-first-time and interference free installation.

Floor-mounted steelwork design provides strong and stable support for structures. By anchoring directly to the floor, it can efficiently handle heavy loads, making it ideal for industrial and commercial buildings. This setup ensures a solid foundation, offering reliable performance over time.

Another benefit is the simplicity of installation. Floor-mounted steelwork often requires fewer adjustments compared to other systems, speeding up the construction process. This can result in cost savings and a more straightforward build, particularly in large-scale projects.

Floor-mounted steelwork also offers flexibility in design. It allows for easy modification or expansion of the structure in the future, accommodating changes in use or additional loads. This adaptability makes it a practical choice for buildings that may need to evolve over time.

Suspended steelwork design maximizes vertical space, allowing for efficient use of the ground level. This is especially useful in areas with limited space or multi-storey buildings, as it frees up floor space for other purposes.

The design also distributes loads more effectively, improving the structure’s overall stability. This results in a more durable and resilient framework that can better withstand various forces over time.

Additionally, suspended steelwork simplifies construction by reducing material use and installation time. This can lower construction costs while allowing easy integration of services like ducts, pipes, and cables.

Structural steelwork loading assessments are essential for ensuring the safety and stability of steel structures. These assessments calculate the capacity of a structure to support various loads, including dead loads (weight of the structure), live loads (people and equipment), and environmental loads (incidental loads, seismic forces). Proper assessment helps prevent overloading and failure.

The assessment process involves evaluating the materials, geometry, and connections of the steel structure. Working to BS EN 1090, VNF uses detailed software models to simulate how the structure responds to different loads. Safety margins are included to account for unexpected stresses or variations in load.